Production

Production

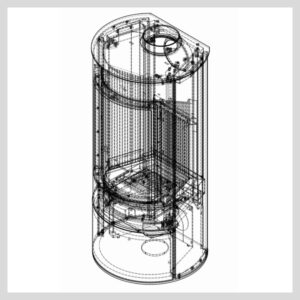

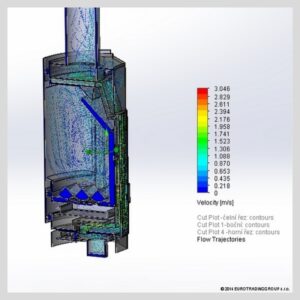

We develop all our models using SolidWorks Professional and FlowSimulation. Each new model grows with us from the initial design concept to serial production and certification in the testing laboratory. We design stoves and fireplace inserts in 3D. We also perform visualizations and combustion simulations. Based on FlowSimulations, we optimize the design solutions for the best combustion results. We create detailed drawings and technological procedures for each part and assembly. We conduct ongoing quality control during production, and each product undergoes final quality control. We manufacture stoves and fireplace inserts in our own facilities covering over 1000m2. In the production of fireplace inserts, we use state-of-the-art CNC technologies for material cutting, forming, and machining. These technologies enable us to achieve high precision in manufacturing individual components, allowing us to maintain high quality standards. For the final surface treatment – painting, we use water-based ecological materials, which require perfect surface preparation and alignment of all painted parts. We achieve this through sandblasting in NC-controlled blasting equipment and our developed degreasing technology. We use recycled materials to the maximum extent possible for packaging the final products. We approach environmental responsibility throughout the entire production process.

Information on orders:

Information on orders:  Technical questions:

Technical questions: